Optimal Timing for Asbestos Remediation

Timing for asbestos remediations depends on various factors including building occupancy, project urgency, and environmental conditions. Conducting remediation during periods of low occupancy minimizes disruption and exposure risks. Additionally, scheduling during favorable weather conditions can facilitate safer and more efficient removal processes.

Remediation is best scheduled when the building is unoccupied or minimally used to reduce health risks and operational impact.

Spring and fall often offer optimal weather conditions for outdoor asbestos removal activities.

Urgent cases may require immediate action, regardless of season, with appropriate safety measures in place.

Avoid remediations during extreme weather events such as heavy rain or high winds to ensure safety and effectiveness.

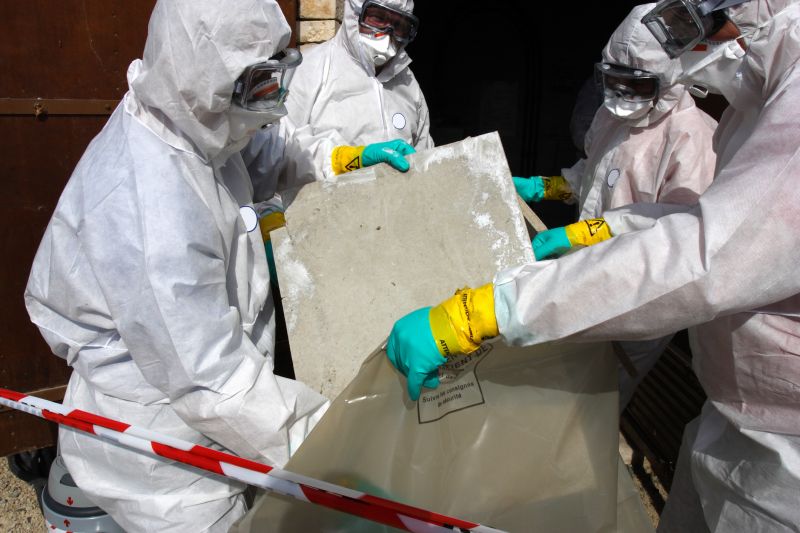

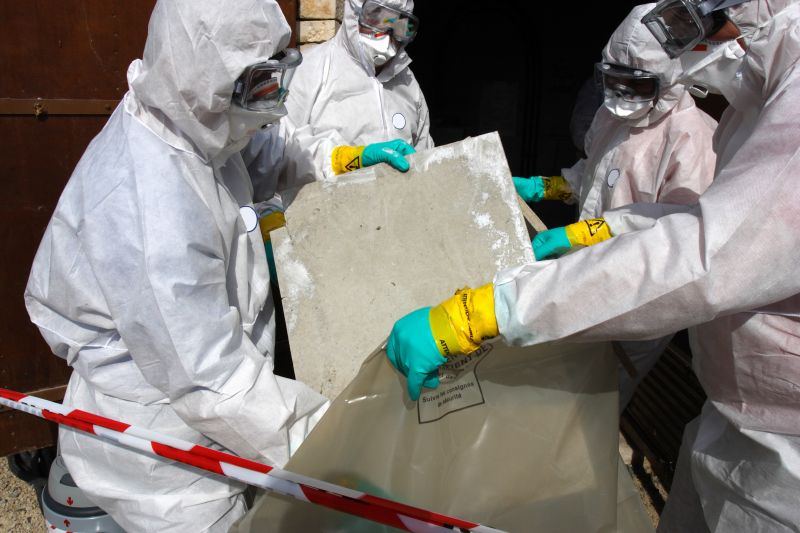

Specialized tools are used during remediation to ensure safe removal.

Proper containment measures are crucial during asbestos abatement.

Protective clothing and equipment are essential for workers during remediation.

Asbestos waste is carefully contained and transported to designated disposal sites.

Asbestos remediations involve specialized procedures to safely remove, encapsulate, or contain asbestos-containing materials. These processes are critical in preventing health hazards associated with asbestos fibers, which can cause serious respiratory diseases. The demand for asbestos remediation has increased due to aging buildings and stricter health regulations. Studies show that proper asbestos management can significantly reduce exposure risks, especially in residential and commercial structures built before the 1980s.

| Aspect | Details |

|---|---|

| Health Risks | Asbestos exposure can lead to mesothelioma, asbestosis, and lung cancer. |

| Regulatory Guidelines | Remediation must comply with local and national safety standards. |

| Cost Factors | Costs vary based on material extent, location, and remediation method. |

| Material Identification | Accurate detection of asbestos-containing materials is essential. |

| Worker Safety | Proper training and protective gear are mandatory for personnel. |

| Disposal Regulations | Asbestos waste requires specialized handling and disposal. |

| Project Duration | Remediation timelines depend on site size and complexity. |

| Post-Remediation Testing | Clearance inspections ensure all asbestos hazards are eliminated. |

Professional assessments identify asbestos locations before removal.

Physical barriers prevent asbestos fibers from spreading during removal.

Proper PPE is essential during asbestos remediation activities.

Designated sites safely contain asbestos waste post-removal.

Ways to make Asbestos Remediations work in tight or awkward layouts.

Popular materials for Asbestos Remediations and why they hold up over time.

Simple add-ons that improve Asbestos Remediations without blowing the budget.

High-end options that actually feel worth it for Asbestos Remediations.

Finishes and colors that play nicely with Asbestos Remediations.

Timely asbestos remediations are vital for maintaining safe indoor environments and complying with health standards. Proper scheduling, preparation, and execution minimize risks and ensure effective removal. It is recommended to plan remediation projects well in advance, considering occupancy patterns and environmental conditions. Regular inspections and testing post-remediation confirm the absence of asbestos hazards, safeguarding health and property value.

Interested in asbestos remediations? Filling out the contact form can provide more information and facilitate planning for safe and compliant asbestos management in various structures.